Accelerated 3D Xray

In-line quality inspection

Automotive is one of many industry sectors which adheres to high quality standards. The cost of not delivering consistent quality products can have high impact. For inspecting the internal of critical parts, automotive manufacturers are seeking for an X-ray computed tomography (CT) solution that fits the production cycle time and that is sufficiently precise. However, due to the inherent approach of CT, the compromise that one has to take between speed and precision cannot always meet the manufactures expectations. Additionally, quality and safety requirements for autonomous vehicles will be even higher and require a zero-defect mind-set. As a result, 100% automated inspection will become de-facto the automotive inspection standard.

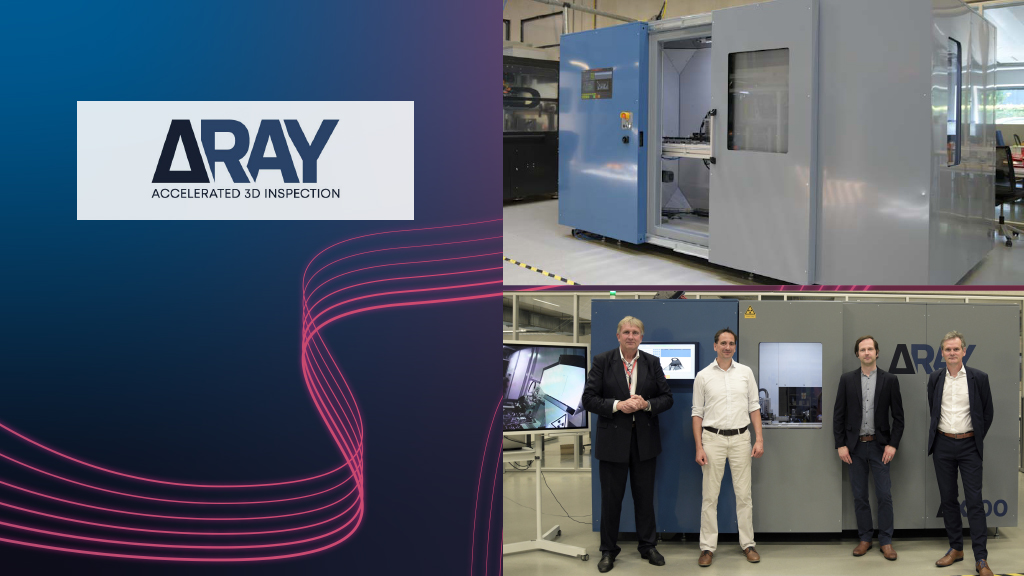

The core of Deltaray’s solution is a disruptive Artificial Intelligence X-ray based inspection solution to perform 100% inspection where sampling-based methods are still used today. It offers a full 3D inspection, of both the internal and external of critical parts, at production speed, using a digital twin to verify the quality of all parts produced at the precision level desired by the manufacturers. The solution consists of a modular, hence broadly applicable and versatile system, that can be integrated in Tier1 or Tier2 automotive production processes. The system is 3D image based with a defect detection resolution of 35-100 µm.

Deltaray’s technology allows for an affordable quality detection set-up beyond the two methods in place today: in-line human visual inspection or sample-based inspection. It also generates data evidence for every part. Data that can be used as a quality trail to address quality complaints or to feed into the manufacturers Industry 4.0 process analyses system.

Back

Back